When a need appears, Albertan communities will rise to the challenge, identifying solutions to problems we never knew we would have.

During the COVID-19 crisis, stories of Albertans coming together and using their resources and creative talents to join the fight have been appearing in every corner of the province, including among rural Albertans with access 3D printers. Line by line, plastic creations such as masks, face shields, and more are being carefully crafted by folks putting their machines to work.

In Didsbury, a community located about an hour north of Calgary, Willy Ridley with Bigfoot 3D Printing has organized the printing of a small mountain of little bands he calls “ear savers.”

“I’ve made almost 2,000 and [have] 1,500 distributed from Calgary up to High Level [so far],” Ridley says.

He originally bought his printers out of curiosity and as a new hobby, making Christmas ornaments, stencils, toothbrush holders, replacement parts for various equipment, items for his trailer, and all sorts of other gadgets.

Now, he has the printers running nearly 24/7 as he creates bands that cross the back of the head, and hook to the elastic on masks to alleviate the pressure and rubbing behind the ears caused by having to wear them every shift.

Originally, Ridley printed just a few, but orders began pouring in.

“It seems to have taken off a fair bit, so we just kept going,” he said.

Ridley is printing them free of charge (cost of shipping only) to any health-care providers in the province who can use them and asks for donations toward the cost of materials from anyone else. Any money over and above the cost of materials will be donated to the Food Bank.

He notes that, with the help of his friend, Brennan Tippe, he can turn out close to 200 ear savers per day with the machines running at full capacity.

Ridley is printing them free of charge (cost of shipping only) to any health-care providers in the province who can use them and asks for donations toward the cost of materials from anyone else. Any money over and above the cost of materials will be donated to the Food Bank.

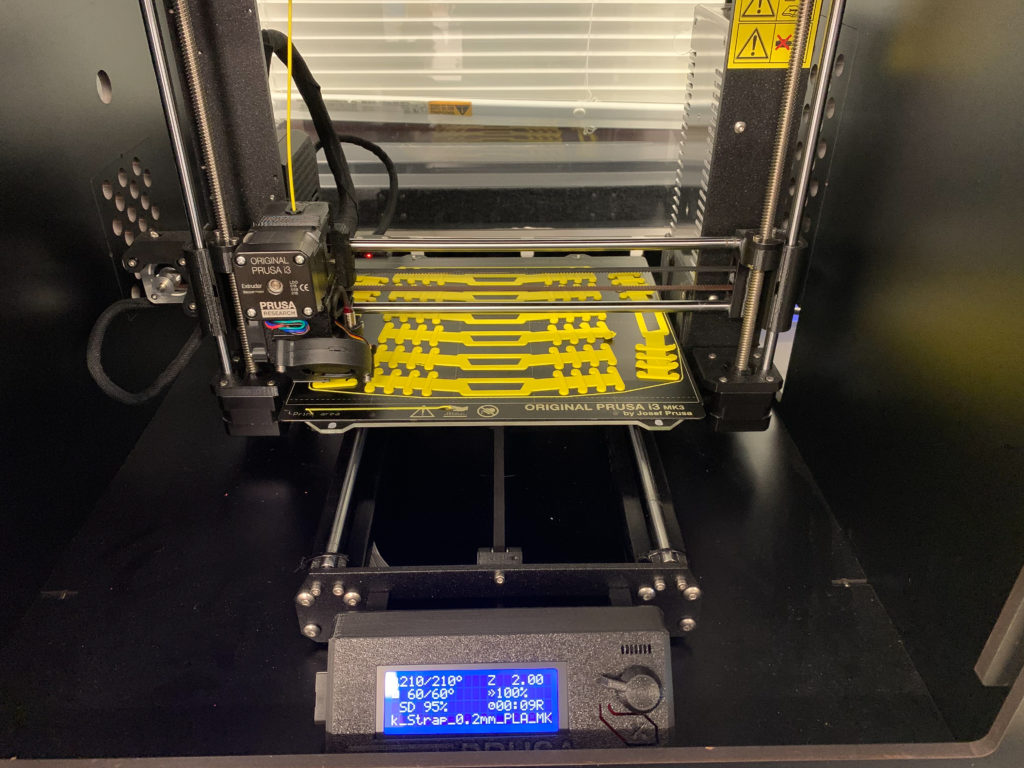

The process is mesmerizing to watch as the pattern is printed numerous times on top of itself. A roll of filament is placed into the machine – Ridley uses low-cost and biodegradable PLA (polylactic acid) – where it extrudes from a tip and creates multiple layers that eventually form a 3D shape. Ridley found a pattern online that takes the least amount of material and time.

Ridley will continue printing as long as orders are coming in. The best way to reach him to place an order through Facebook at Bigfoot 3D Printing.

A few hours away in another rural Alberta community, a local school’s 3D printer is being put to good use while the students are learning at home.

East of Edmonton in Smoky Lake, Murray Lalonde, an instructor at H.A. Kostash School, has been helping use the printer to trial-run some full-face shields.

“It’s really neat how precise this thing can make these objects,” Lalonde says, adding that another H.A. Kostash teacher, Craig Stinson, had been previously using the printer to teach students to create all sorts of objects such as puzzles and model rockets.

Rather than let the printer sit unused, they decided to make something that could help others in the community.

Stinson taught his colleagues, teacher Sarah Feledichuk and principal Dick Richards along with Lalonde, how to find the patterns online and load them into the printer.

Lalonde says the machine can print face shields with slotted bands where a sheet of clear material similar to thick acetate can be inserted, protecting the person’s face from germs in the air.

Each face shield takes about three hours to make.

So far, they have printed 15 face shields and they are perfecting the printing process as they go. Like Ridley in Didsbury, they have also been printing ear savers.

Lalonde also remarked on how great it is to see communities come together to help each other. He insists that if any business in Smoky Lake needs the shields, they are encouraged to reach out to the school directly.